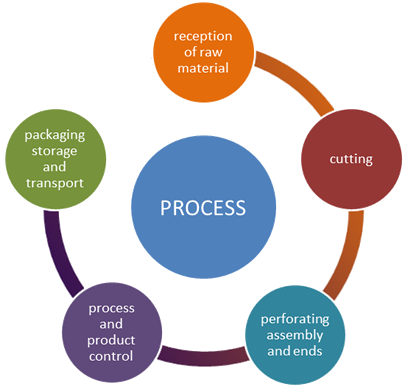

Desalu's working process

Reception of raw material

At reception of raw material -and after inspection for bumped ends, deformations or any damage- the bundles are placed in the warehouse near the cutting area, ready to be fed into the automatic cutting machines.

Cutting

Tubes are cut to the dimensions specified by customers in our automatic cutting machines with deburring, washing, drying and loading processes; offering a clean neat finish.

Special mitred cut possible.

Tolerance ±0.5 mm

Perforating, assembly and ends

Tubes are perforated to meet customer requirements on our perforating machines.

Tooling is designed and developed in our in-house tool shop.

When the piece requires it, we weld, assemble and/or provide special end finishing (star, nozzle, end calibration, mitred cut…)

Process and product control

All employees carry out routine inspection of pipes throughout the different processes: cutting, perforation, welding, assembly…

They receive in-company training on how to use measuring equipment, basic concepts on tolerance and care of measuring instruments.

Quality control is a concern of all our workers and it is monitored and assessed by the Quality Department.

Packaging, storage and transport

Pipes come out of the perforating and assembly process clean, so they are ready to be packed and stored.

Pipes are usually put in metal containers (gitterbox) or carton boxes on demand and according to business agreement.

They are clearly labeled for expedition on ground until they are loaded on to the lorries.